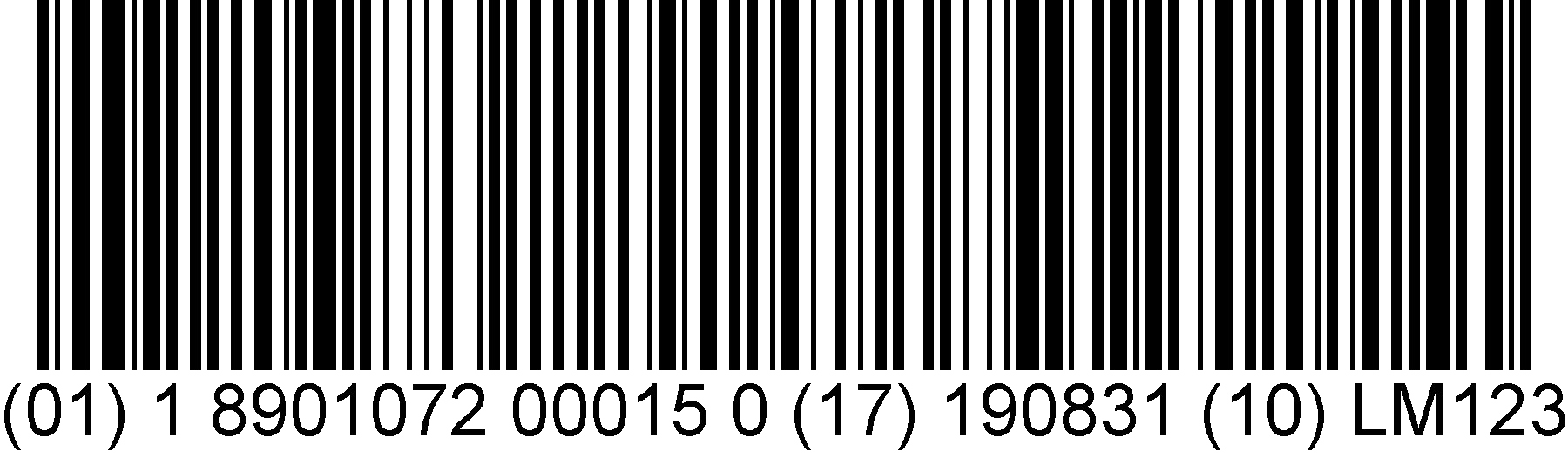

TRANSPARENT BARCODE REGISTRATION

It is recommended to allow slightly more than the minimum required quiet zones, in case of ink spread or plate registration issues. The minimum size of the quiet zone depends on the size of the barcode. If it is reduced or eliminated, the barcode may not be able to be scanned. The quiet zone is very important – it tells the scanner where the beginning and end of the barcode is. For two-dimensional barcodes, the quiet zone is the light area around the barcode. Quiet zones are the clear areas before the first bar and after the last bar on a barcode.

TRANSPARENT BARCODE MANUAL

Worse, it may not scan at all – therefore requiring manual input of data, which introduces errors and inefficiencies. At the wrong height, a barcode may not scan first time. Regardless, you should avoid reducing the barcode height (known as truncation) from what is specified. Other barcodes, such as ITF-14 and GS1-128, have a set height with some exceptions for different applications. This is because of the way the scanner scans this type of barcode. For some barcodes, like EAN/UPC, the height must remain in proportion to the width to avoid scanning problems. Request a barcode size gauge Barcode heightĪll GS1 barcodes have certain height requirements. While not a precise measuring tool, it is useful during packaging/product design to determine the amount of space needed for the barcode. The GS1 barcode size gauge shows the sizes of EAN/UPC and ITF-14 barcodes at different magnifications. Your printer should be able to advise on the suitable size for your packaging, printing method and design.

All GS1 barcodes have a minimum and maximum size requirement. Generally, bigger barcodes scan more reliably. The minimum size of the barcode depends on the barcode type and the intended scanning environment (point-of-sale, warehouse, etc). Things to consider when designing barcodes Barcode size

TRANSPARENT BARCODE HOW TO

This user guide provides an overview of how GS1 barcodes work and how to apply them.

0 kommentar(er)

0 kommentar(er)